Flayed carcasses, flesh under the finger nails, pits of bubbling chemicals, scrapers and nasty smells: it was all in a day’s work for the leather-workers at Rusland Tannery.

You can visit the spot for yourself - it's between Haverthwaite and Satterthwaite, west of Windermere.

In the eighteenth century, when this tannery was in its heyday, leather was in constant demand - from saddlers and shoemakers, hatters and upholsterers. Rusland Tannery had everything it needed close at hand: tree bark, lime, livestock and manpower.

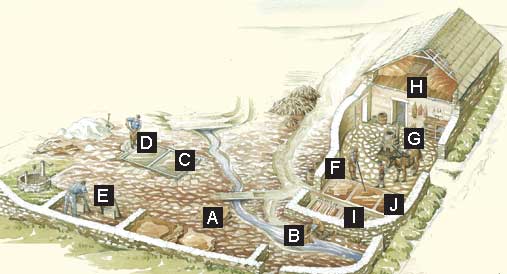

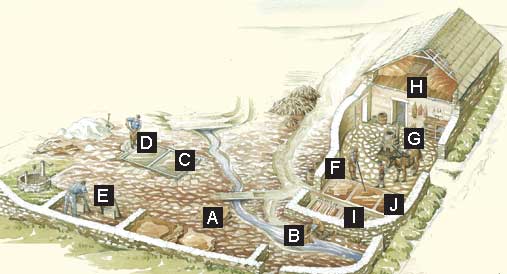

The preparation of leather, from raw animal hide to quality clothing material, was a grisly business:

- Local tradesmen would bring in dried and salted skins and hides from slaughterhouses and markets in the area. In this rigid state they were unworkable - see A.

- The first job was to wash off all the dirt, blood and salt preservative - see B.

- The next stage was to get rid of the outer layer of skin and hair and the flesh beneath the hide, by first leaving the hides in a pit of lime solution - see C.

- The saturated hides were dragged from one lime pit to the next - see D

- Each hide was then scraped over one of the two beamstones and worked with curved blades until only the middle layer of the skin remained - see E.

- To condition the leather further the hides were usually steeped or rubbed by hand in unmentionable substances like warm dog muck or cold chicken manure.

- The next step was to transfer the hides to tan pits in the building - see F. Tannin preserves leather and keeps it flexible. It occurs naturally in tree bark, especially oak. Nearby oak coppices had their bark stripped and stored in special barns before being delivered to the tannery.

- The bark was stored at road level so it could be fed into the horse-powered crushing mill - see G.

- The dusty ground bark had to be kept dry, so it was then stored loose in the loft - see H.

- The tan pits contained tannin-stained water of varying concentrations, with each hide held firmly in place to avoid blemishes in the tanning process - see I. After being shifted around these ‘suspender’ pits of different solutions the hides became soft and porous .

- They were then laid flat, ready to be placed in layers and stacked with ground bark between them - see J. Sometimes they stayed in these layers for weeks or months.

- Finally, they were removed, washed with weak tanning liquor, then oiled and taken to a suitable space to dry.

- Once dry, the tanned hides were ready to be made into essential leather goods such as a horse collar and harness, belts, boots or hat.